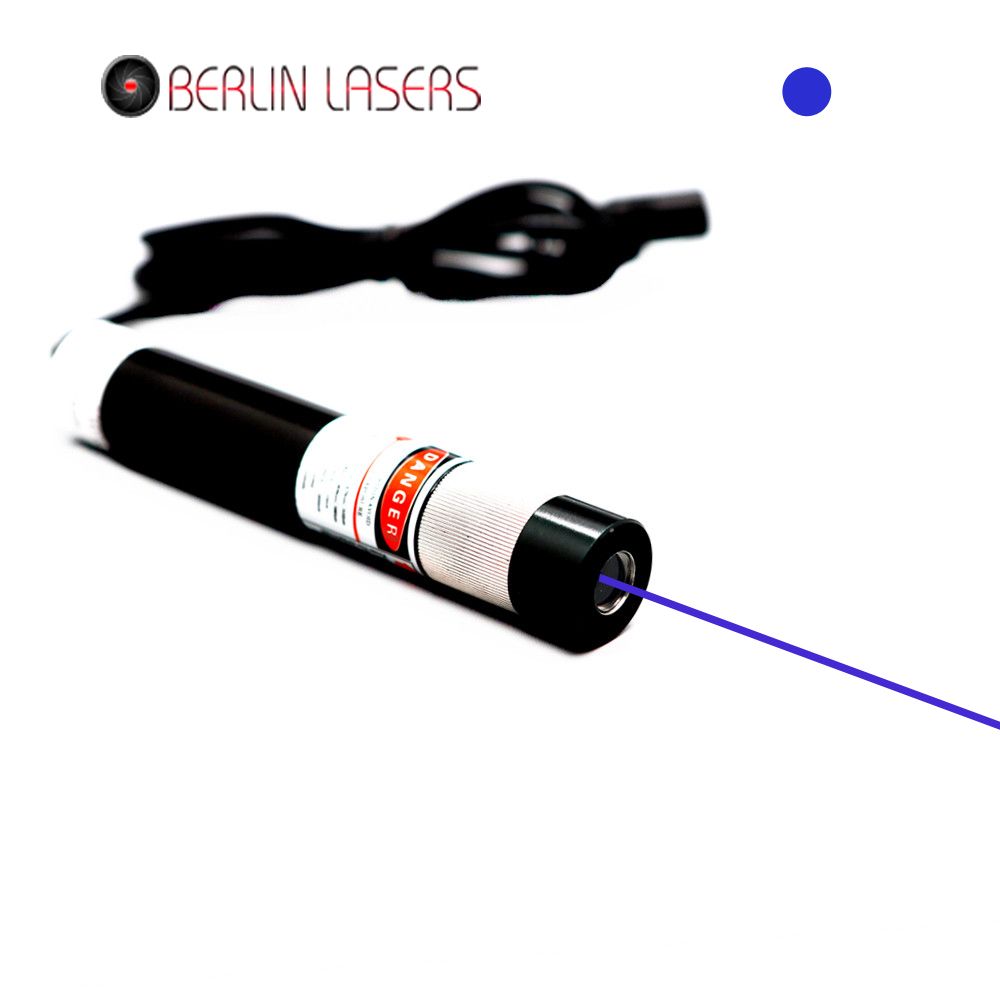

Whenever dot measuring work is processing for those of industrial precise machinery processing works, it would be a much preferred choice for users to operate a high energy density device, such as a 445nm blue laser diode module. It has high photon energy and can concentrate higher energy onto a smaller spot area, thereby achieving efficient material processing. Based on the use of an import 445nm blue laser diode and qualified optic lens inside a durable metal housing tube, only after its connects with constant electric power source supply, this direct diode emission made blue dot laser makes sure of easy reaching, good direction and high precision dot measurement and alignment for some high hardness materials effectively.

Among all visible laser devices, owing to its much short wavelength of 445nm, the basic operation of a blue laser diode module gets small diffraction limit, which can achieve high precision focusing and spot control. It applies an import 445nm blue laser diode within 50mW to 100mW and high power up to 150mW to 500mW. Only if it gets basic use of a metal heat sink cooling system inside a different dimension metal housing tube, available with 16mm, 18.9mm and 26mm diameter tube design, this dot laser alignment tool just enables quite easy carrying, good heat dissipation and ultra long time lasting blue reference dot projection in continuous use. The processing accuracy of blue dot projection can reach micron or even submicron level, which can meet the requirements of precision processing.

In front of beam aperture part, 445nm blue laser diode module is equipped with a qualified glass coated lens and a glass window. After its connects with an AC/DC adapter with 100V to 240V operating voltage acceptation, it gets high energy density and high transmittance blue laser light source at long extending distance immediately. Usually it gets good blue laser beam mode, small laser beam divergence angle, which can ensures the laser beam stability and consistency of the laser during transmission. Based on its correct use of output power and operating voltage electric power source supply, this accessory part of a 445nm blue dot laser always makes a good job for improving processing quality and repeatability in long time lasting dot measuring works.

Multiple Applications in Industrial Fields:

Precision marking: the accessory part of a 445nm blue laser diode module can be used to mark various metal and non-metal materials with high precision, such as product model, serial number, QR code. The blue laser dot marking is clear, permanent, and has little damage to the material surface.

Micromachining: It is suitable for the processing of tiny structures, such as micro-hole processing, micro-groove processing, etc. It can achieve micron-level processing accuracy and meet the processing requirements of some high-end precision parts.

Alignment and positioning: On industrial production lines, blue alignment laser dot can be used as a benchmark for precise dot alignment and positioning to help accurately place and assemble parts, improve production efficiency and assembly accuracy.